FAQs

Frequently Asked

Questions and Facts

What are ‘emulsified fuels’?

Emulsified fuels are used worldwide as high-quality, eco-friendly fuels. Emulsified fuels deliver fuel savings due to their more complete combustion, while reducing emissions of hazardous substances.

The global emulsified fuel market is worth billions of dollars a year and is growing. The biggest market share belongs to the energy sector and marine fuels.

Here there are moves to reduce sulfur content and CO2, NOX and particulate emissions. For as long as the world’s refineries struggle to satisfy the need for fuel oils with these higher specifications, the use of water-emulsified fuels provides an efficient solution to this problem. The efficiency and effects of emulsified fuel have been proven in practice worldwide, as well as in numerous scientific studies and tests.

What are the advantages of FOWE?

The known and proven advantages of emulsified fuels are listed below:- More efficient and complete combustion

- Reduced emission of hazardous gases

- Reduced fuel consumption

How does FOWE compare to regular heavy fuel oil?

Example 1

The superiority of emulsified fuel is shown in the chart below.

Emulsions with 10% and 25% water content combust faster and achieve higher combustion temperatures (approximately 180°C) compared to heavy fuel oil.

Source: An Experimental Study of the Effect of Water Content on Combustion of Heavy Fuel Oil/Water Emulsion Droplets (Ocampo-Barrera, Villasenor & Diego-Marin, 2001).

Example 2

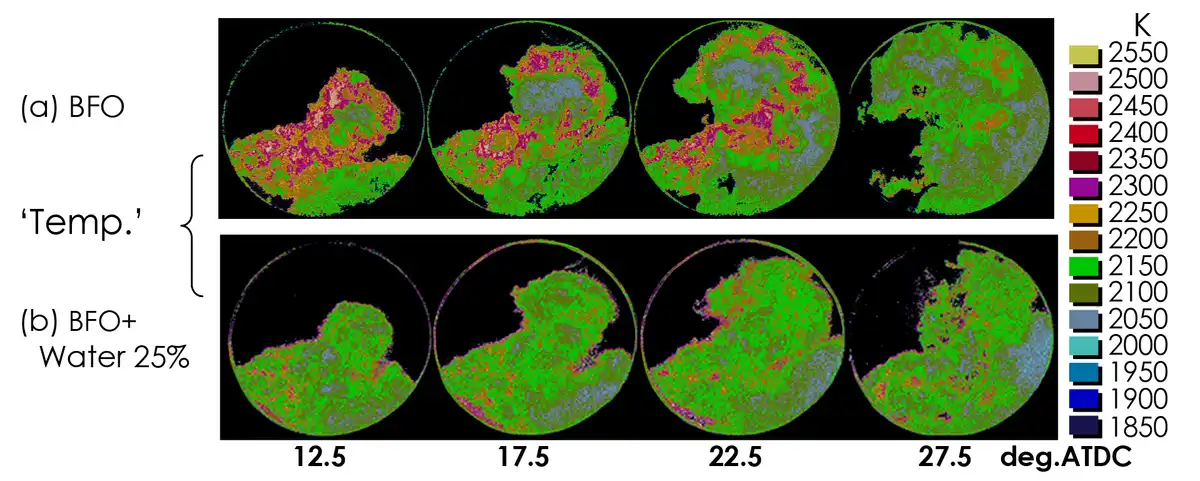

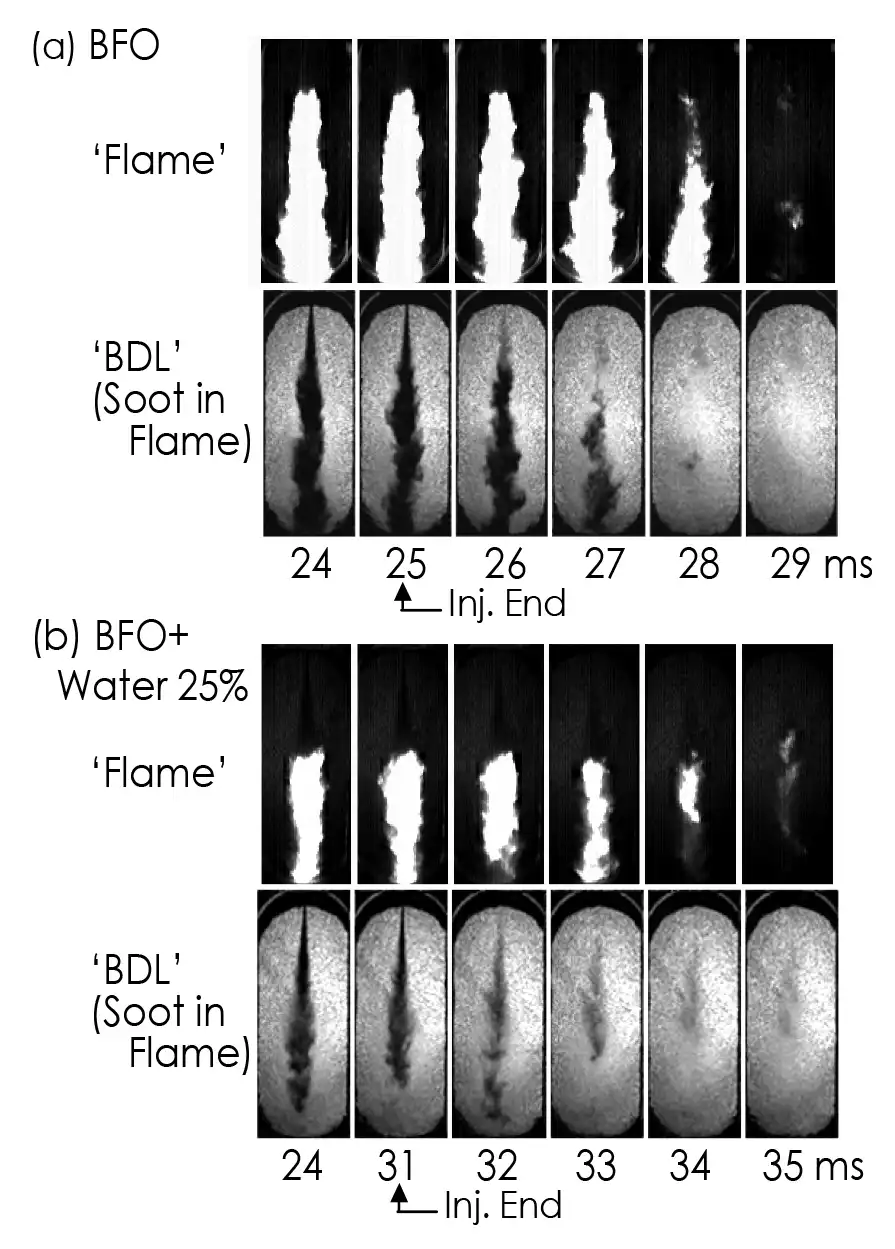

The following example is taken aVisual Study on Combustion of Low-Grade Fuel Water Emulsion (Tajima et al, 2001).The study included a comprehensive test of heavy fuel oil and emulsified fuel (with 25% of water content) combustion in a marine diesel engine.

The figures below show a more complete emulsified fuel combustion compared to heavy fuel oil. The combustion of heavy fuel oil results in the formation of big, red zones of high temperatures in the cylinder, which favour the formation of NOX. These zones are considerably smaller in the case of emulsified oil combustion, which is why the formation of NOX is reduced.

The conclusion is that water-emulsified fuels efficiently reduce NOX emissions, as well as fuel consumption, without any effects on the state of the engine.

Does viscosity increase in emulsified fuel and how to deal with that?

When water is added by emulsification process, the fuel viscosity increases, due to interfacial films surrounding water droplets. Anyhow, the injection temperature does not need to be increased, on the contrary even decrease due to easier atomizing of the emulsion compared with pure fuel. Such improvements are rendered possible by micro-explosions (“puffing”). During combustion, water droplets in the fuel evaporate, and the vapor thus becomes pure fuel given the difference in boiling point between water and oil. Puffing is initiated when water vapor has accumulated to a certain level inside droplets. Puffing enhances droplet atomization and evaporation, and reduces GHG emissions.Why FOWE emulsion is strong?

The exceptional stability and strength of FOWE emulsion, without chemicals and additives, are achieved for 4 reasons, which are made possible by using the unique FOWE CCT technology.

- Due to the high energy of cavitation, water in the gas phase ideally occupies the space (FO), which is why 100% homogeneity of the emulsion is achieved.

- FOWE CCT technology enables the creation of small water particles in FOWE emulsion (micro size), so that there is practically no influence of gravity.

- The additional strength of the FOWE emulsion was achieved due to the dipole character of the water molecules. Due to the complete homogeneity of the emulsion, the poles of the water molecules are ideally oriented in the oil, in accordance with the polarity. In this way, the emulsion is stronger due to the electrical interaction of the opposite pole of water molecules. We can imagine that the emulsion is structurally reinforced, with threads of electricity (like reinforced concrete).

- In the ideal arrangement of oil and water in FOWE emulsion, each water particle is surrounded (encapsulated) with oil. Due to the large difference in boiling point (=200 °C) between oil and water, temperatures above 100 °C cannot evaporate a water particle from the emulsion, because the oil layer around it absorbs heat and protects the water particle from evaporation. FO absorbs heat and protects the water particle from evaporation. Evidence: Test (STI Conaught, Venice – Port Said, September 2001), carried out on a MAN diesel marine engine, showed that the FOWE emulsion remains stable at 130 °C (in the tank), without water evaporation.s

Glossary of terms

Emulsion is a mixture of two or more liquids that are normally immiscible. Emulsion is an unstable mixture which, in the absence of an emulsifier, soon separates into its ingredients.

Emulsifier is a substance that keeps the emulsion stable.

FOWE stands for Fuel Oil Water Emulsion, an emulsion of heavy fuel oil and water without additives. With the help of hydraulic cavitation, FOWE technology can produce a stable emulsion of fuel oil and water.

Hydrodynamic cavitation is a physical phenomenon that occurs in the vicinity of sudden pressure drops in water or other fluids. This phenomenon occurs due to rapid changes in fluid flow, caused by device design, allowing fluids to move from liquid to gas and back to liquid again. All of this happens very quickly and locally in the device. During the changes in the fluid’s aggregate state, energy is released. Depending on the intensity, the energy homogenises mixtures of different fluids or breaks down the fluid molecules and changes the fluid’s chemical composition. FOWE technology has proven that hydraulic cavitation can increase process conversion and produce a stable emulsion of heavy fuel oil and water.

Cutter is a refinery fraction from the diesel components pool which, in the process of blending of commercial heavy fuel oils, reduces viscosity and sulfur content. FOWE technology eliminates cutter consumption by using water as a cutter instead of a diesel fraction, which results in the increase of the amount of diesel fuel.

Low NOX technology (LNOXT) disperses fuel oil into the smallest particles possible. LNOXT uses fuel oils with low viscosity and high pre-heating temperatures to achieve low NOX emissions. This increases costs because the cheapest fuel normally has high viscosity and requires diesel fractions for fuel oil blending. FOWE technology eliminates the need for LNOXT.